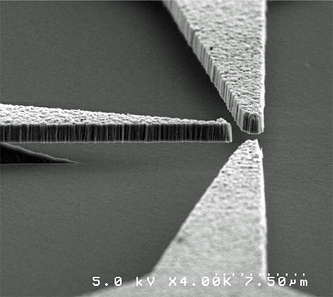

Scanned Electron Microscope image of a triode made from nanodiamond thin film that shows how the diamond components are cantilevered over a silicon dioxide substrate. (Photo: Davidson Laboratory, Vanderbilt University)

Looking to build a hardy new generation of electronic integrated chips, electrical engineers at Vanderbilt University are looking to the world’s hardest natural substance – the diamond.

The team is considering the gem for use in electronic chips which might be used in extreme environments. Silicon semiconductor material is commonly used to make the chips right now.

The Vanderbilt team has been able to develop and build many of the chip’s basic components – such as transistors and logical gates, which both are key in creating these electronic circuits – by using thin films of nanodiamond, which is usually produced by the detonation of a diamond blend.

Along with an ability to operate in harsh conditions, including radioactive or extreme temperature environments, the nanodiamond-based components also have the potential to operate at higher speeds while using less power than the silicon-based versions.

Of course, anytime you talk about diamonds, the first thing many people think of is cost. But, according to research Professor Jimmy Davidson, even though their chip design does use a diamond film, it is not really that expensive.

In fact, since electronic units are so small, the researchers estimate that around one billion of them can be manufactured from just one carat of a diamond.

The nanondiamond films are made through a widely-used method called chemical vapor deposition (CVD), a chemical process which produces high-purity, high-performance solid materials frequently used in the microelectronics industry.

Diamonds in this form are said to be less than one-thousandth the cost of quality jewelry diamonds.

They’re so inexpensive that a number of companies already put diamond coatings on tools, cookware and other products. With this in mind, researchers figure the cost of producing the nanodiamond devices should be competitive with those made from silicon.

The research team describes its nanodiamond circuits as a hybrid of electronic technologies; a unique combination of the best qualities of old-fashioned vacuum tubes and modern solid-state microelectronics.

The Vanderbilt team explains that its devices are first built on a thin film of nanodiamond that is then overlaid on a layer of silicon dioxide.

This combination mimics the use of vacuum tubes, since the electrons move through a vacuum between the nanodiamond components, instead of flowing through solid material the way they do in normal microelectronic devices.

Because of this, the nanondiamond-based devices require vacuum packaging in order to operate.

The potential applications for this nanondiamond chip include use in military electronic devices as well as electronic and computer circuitry needed to operate in space.

With a little bit of modification to allow them to be packaged in a vacuum, these nanodiamond devices, according to the research team, can be made by virtually the same processes currently used by the semiconductor industry.

I dreamt about this possibility 16yrs ago.how do I take part in this project?

I suggest that you perhaps contact someone at Vanderbilt University who worked on this project… this links to a press release at Vanderbilt University. Hope it helps… Good luck…

http://news.vanderbilt.edu/2011/08/nanodiamond/

I hope this new technology will be kept as a US trade secrete and used to create jobs at home. Nothing worse than inventing something then outsourcing it abroad.