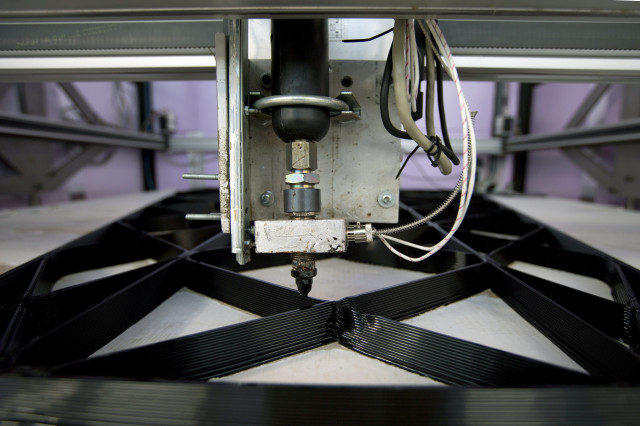

A 3D printer constructs the building blocks for a canal house in Amsterdam, Netherlands, March 13, 2014. (AP)

The potential of 3D printing is unmistakable, even though the industry has just begun to scratch the surface of that potential.

Consumer 3D printers are just making their debut in U.S. stores. Their industrial counterparts are already complementing manufacturing in developed countries, even as others assess their market growth potential.

But is this a new industrial revolution? Two industry experts offered TECHtonics widely divergent views on the future of 3D printing.

Tim Caffrey, a senior consultant with Wohlers Associates, says manufacturers of 3D printers for consumers “would like us to believe that they will be as commonplace as personal computers are today.”

But he says his company does not “necessarily see that happening with the general purpose consumer 3D printer just because of limitations in materials and the fact that most people are not designers.”

The advantage of 3D printing or additive manufacturing (AM) is the ability to create complex parts relatively inexpensively. But according to Caffrey, today’s consumer 3D printers are too slow, use a limited range of materials, cannot build assemblies and do not include embedded electronics.

“When it comes to real manufacturing, we still have a ways to go with these inexpensive, material extrusion systems,” he said. “They are still just making ABS – which is a type of plastic – ABS thermoplastic parts that are fairly rough and have limited applications.”

Most industry growth and new applications are taking place on the industrial side with $200,000-plus machines producing metal parts or high-accuracy thermoplastic parts, mostly in the medical and aerospace sectors.

Handicapped Haitian boy Stevenson Joseph learns to use a 3D-printed prosthetic hand at the orphanage where he lives in Santo, near Port-au-Prince, April 28, 2014. (Reuters)

These industries are a perfect fit for 3D printing because “they typically have a fairly low production volume … and also because the parts in those two industries can be either custom or in some cases, fairly complex,” said Caffrey.

But in the end, he views the technology as just another form of manufacturing that compliments existing methods.

“While we could say it is a disruptive technology for certain markets, for certain applications, it is not necessarily going to displace traditional manufacturing,” he said.

Some products, like the ubiquitous 12-ounce aluminum cans or plastic cups produced by the millions “will probably never be manufactured by additives because it is economically unfeasible,” he said.

AM has to be “evaluated on a case-by-case, part-by-part basis to see if it is economically advantageous, or if it creates parts that are superior because they deliver more value or greater customer satisfaction or all three of those things,” he added. “And if it doesn’t, then companies are not going to change their manufacturing methods.”

The major drawback in industrial applications is that 3D printing “is limited in its scalability, and does not benefit from the same economies of scale that you see in traditional manufacturing techniques,” says Joe Kempton, a 3D printing research analyst at Canalys, an analyst firm that focuses on technology.

Nevertheless, 3D printing’s customization potential, convenience and manufacturing efficiencies have been driving growth and presenting several advantages over many conventional production methods.

“As an additive production method, waste is reduced,” said Kempton in an email interview. “And there are no costly setup expenses. And 3D printing ultimately promises the ability to quickly, easily, and locally source a 3D representation of a digital design without having to wait for goods to be shipped from remote production facilities.”

While specific 3D printing materials will still have to be imported, developing countries investing in 3D printing education and training will be able to retain local talent and foster innovation, says Kempton. And the convenience of creating prototypes locally improves time to market and triggers a spill-over effect into other manufacturing areas.

“Being able to produce objects within the country and reducing imports improves self-sufficiency, increases employment through local businesses development, thus increasing local investment and consumption and, therefore, the average standard of living,” he said.

But the biggest investors are the developed economies whose manufacturing base has moved to Asia. With education, improved printing capabilities and wider use, Kempton projects a “technological race” among competing economies to become “the global manufacturing leader in 3D printing.”

That puts developing countries at a disadvantage. Given the complexity of 3D printing, Kempton says developed and rapidly developing countries are already ahead “both in terms of 3D printing adoption and technical readiness for the demands of 3D printing.”

“We are unlikely to see an unusual success story from a small developing country,” he added.

But the potential is huge for a big player like China, which has been using AM in its aerospace applications and has seen the fastest growth, partially due to heavy government investment.

“Rather than playing catch-up as it has done in the past with previous manufacturing processes, it now has the potential to lead the way in a new one,” said Kempton. “China will have the ability to create 3D printers and materials on a massive scale, with a large and increasingly better-educated workforce to turn the country into a 3D printing powerhouse.”

Japan and South Korea are also seeing market growth at “remarkable speeds. And in the long-term, Kempton says BRIC countries – Brazil, Russia, India and China -can become “significant markets” for 3D printing innovation.

“This is a technology which is going to transform the manufacturing landscape,” said Kempton. “But it is important to keep advances in perspective.”

4 responses to “3D Printing Grows, But is It an Industrial Revolution?”

Finally! Someone who actually understands 3D printing, which is definitely NOT an industrial revolution. This technology is so oversold it is ridiculous. While useful in a few niches, it is not going to unseat far faster and more developed technologies. How do I know? For one, I run a contract manufacturing business that makes thousands of parts a year for large aerospace and electronics companies. We pick the technologies that make sense for the customers and produce parts in the least time, with the highest quality and the lowest cost. 3D printing doesn’t even come close. This is a major stock bubble due to burst very soon. Good article!

Contract manufacturing for aerospace and electronics is a footnote of the 3d printing capabilities.

Sure, production now of pvc/abs parts are better with injection molds and steel rods in China, but the advantage that 3d printing has over clunky traditional methods is pretty vast. Undercuts are non existent with most industrial 3d printing processes, for example. That alone is a huge advantage, but it has yet to be utilized because our need for new technology hasn’t been met with the demand yet.

Any issue I hear with 3d printing in regards to comparisons with traditional methods fall into three categories: time, build space, and quality. If you really think the largest players in the industry don’t already have an R&D department working on this than you should do some reading.

what is the price of the 3d printer

The consumer printers run anywhere from $500-3,000, not counting material and supplies, which shouldn’t be too expensive.